Backed up with a powerful team, we have our excellent in-house processing facilities that are far apart the other industries with best in-class eminence and care. We are one amidst the preeminent steel corporations in giving our customers the highest value to their needs. Packed up with sundry services our unique stand for service lies in uplifting our customers' desires to gratification.

Before the steel is been processed, it contains a surface scale or rust that should first be removed for obtaining a clean substrate. There are several processes for coil pickling and we at 'Modern Age Metal Processors' make our process unique in using the push and pull shallow bath with hydrochloric acid. The acid actively removes the iron oxide sticking to the surface of the steel with help of a rinse session that contains a dryer. This process continues to a diverse range of pickling tanks and the hot water removes the dirt attached on the surface of the steel. After which several processes are carried out in steel processing.

When it comes to technology, we have the contemporary technical equipments required to muster up the works and make it look unique. ' Coil Slitting' is one of our services that helps in cutting the coil to the exact size as requested by our customers.

This process includes the functioning of rotary knives, that helps in cutting the coil to narrow widths, which are called as strands. These are again recoiled for obtaining the finished width slit coil. The two driven arbors appended with the knives helps in slitting the coil to the exact size that is ordered. It can be resized to petite sizes by recoiling by finished mandrel that produces ample of narrow coils.

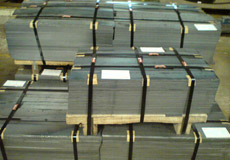

One of our services include de-coiling where the parent coil is made flat and then cut into sheets. The obtained sheets are diverse in their lengths and are cut according to the consumers needs. Through a leveling head the other coil is passed where there are hardened rolls that controls the pressure. The correspondent length is cut using a shear and then fed for obtaining bundle of quantity. It is then dispatched by migrating these bundles to banding area in which they are moved in carefully and customers can collect the material straight away.

We at 'Modern Age Metal Processors' run down the shearing and blanking processes that helps for cutting the sheet in exact size and shape. The shearing process includes the cutting method with a shear force which makes cut along the width of the coil. This is well-done for thin materials and our experience team, work out this process in ensuring high quality in controlling the width. This process also involves:

Special Packing is an art. We at "Modern Age Metal Processors" have mastered the art of special packing and have proven our strength even with the use of latest technologies. We support diverse range of packaging services based on your application needs. Our packing uses fibers and braiding process that is specifically developed to suit the field of application. Shipping is made easy for all your different marketing with our crating, palletizing and foam-in-place packaging.

Management and control of a warehouse is the most complex task in any Steel Industry. We at "Modern Age Metal Processors" manage our warehouse with ease using Warehouse Management System that caters to our business needs and safety.

The right storage location is determined for every item based on actual geometrical area and flexibility. This also considers our plants material flow to meet technical delivery of our product to you. The system performance and maintenance capabilities of Warehouse Management System supports every technician to physically allocate product storage space after considering all factors of physical characteristics.

Logistics handling is the key to continuous business with our customers and corporation. We at "Modern Age Metal Processors" value both your physical and abstract terms and conditions to ensure a smooth delivery of your products from our plant. Our configuring mechanism helps understand the various complexities involved in the logistics management process. We streamline the process to provide on time quality delivery with value-added service. Tracking and tracing being the essential key part of logistics, we consider product safety and reliability issues.

©2015 Modern Age Metal Processors | All Rights Reserved

Powered by crazypencilz